Infrastructure

PRODUCTION AND MARKETING

Our advanced infrastructure enables large-scale production of industrial metal castings. Equipped with state-of-the-art machinery, we ensure smooth production and rigorous quality control through our well-equipped Testing facility.

SAND PLANT (FULLY AUTOMATED)

Our sand plant boasts a capacity of 25 tonnes per hour, supported by two intensive and mixers . Designed with precision, it controls sand and additives through load- cell arrangements. The sand hopper has a capacity of 200 tonnes (2 units of 120 tonnes each), and the plant includes two shake-out machines and an underground conveyor system.

Conventional Machine Moulding Line

The moulding l ine features simultaneous jolt squeeze and pin lift machines with a track line system.

We currently operate the following:

v ARPA 300 Machine : 2 pairs Box size:

520 x 400 x 200 mm

(500 sets)

v ARPA 450 Machine : 2 pairs Box size :

700 x 650 x 250 mm

(75 sets)

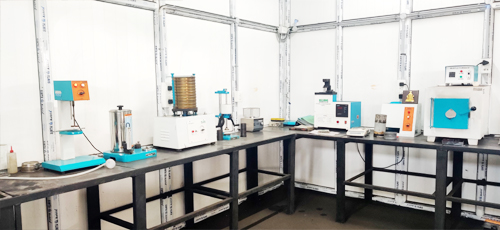

Quality Management

We are ISO 9001:2015 certified, with a dedicated division for quality management across all stages of the casting process, including incoming control, post-processing, and final inspection. Our skilled team of inspection engineers ensures the production of flawless quality castings.